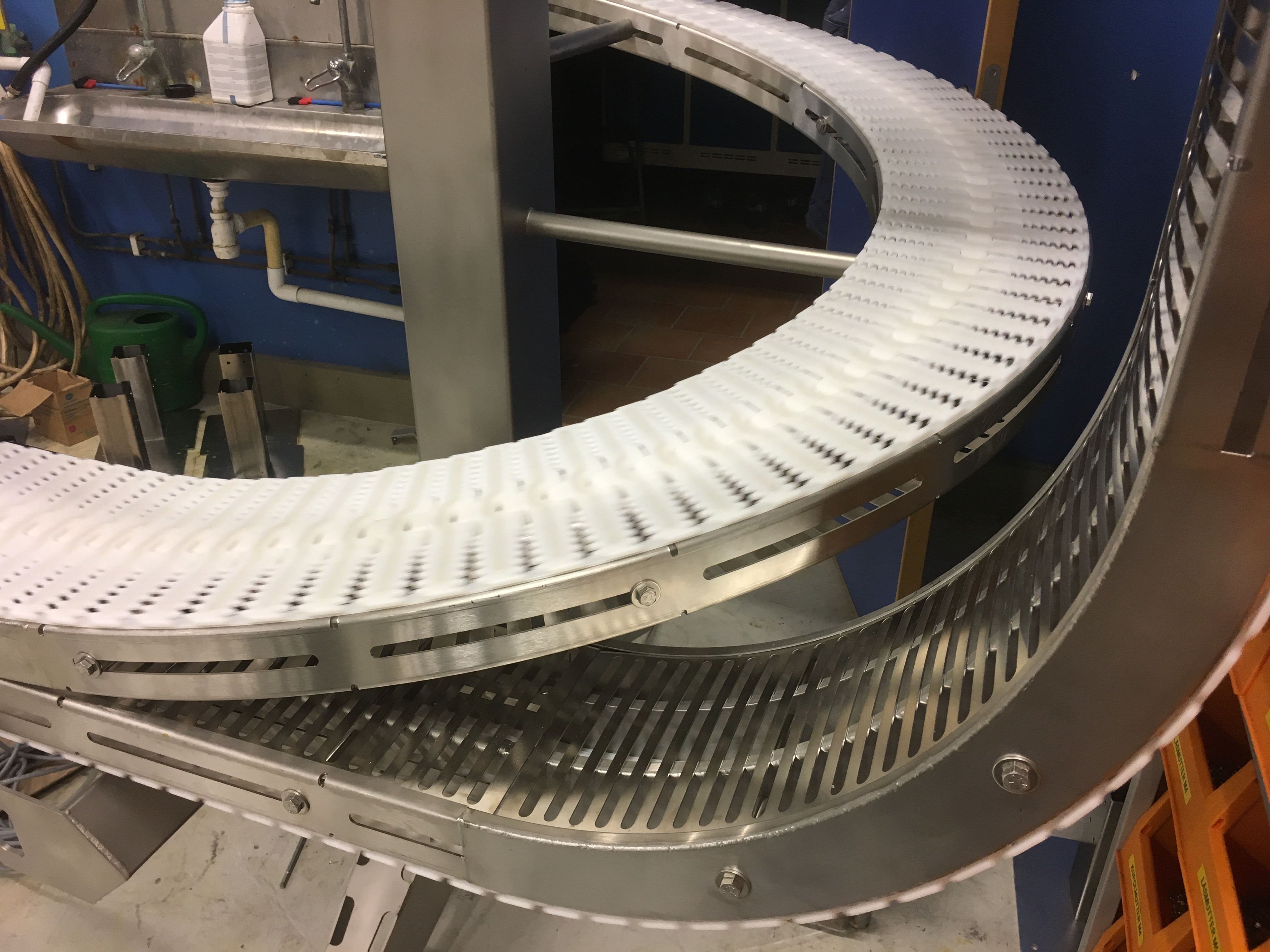

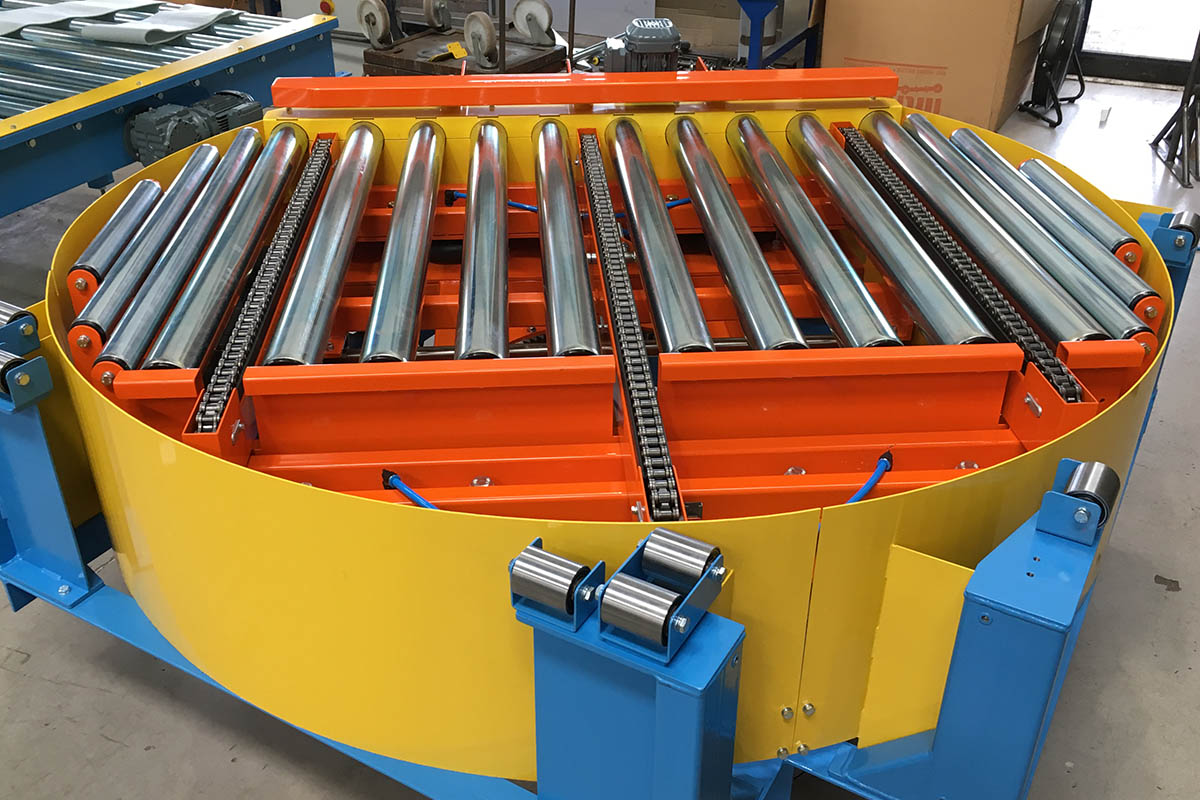

The Reko engineering team will follow either a SOW and/or a field onsite engineering evaluation. Sortation conveyors can be specified for use within a wide range of applications to suit the various production locations and environments. Construction and Specifications of Sortation Conveyors

Conveyance systems manual#

By minimizing or eliminating the need for manual operator involvement, they enable facilities to identify, sort, and/or mark products with faster processing speeds and greater processing accuracy.

These systems employ the use of stock-keeping unit (SKU) numbers and other unique identifiers to automate the sorting, reordering, converging, and diverging of products on processing lines. Recent advancements in material handling technologies have led to the introduction and adoption of smart conveyors. Since products are processed faster, the time between receipt of the order and delivery of the product is much shorter, resulting in better overall customer satisfaction with the facility’s service. The higher productivity achieved by using conveyors for sorting operations translates to lower production costs since facilities can spend less on manual labor to process greater amounts of products in a shorter period. Using conveyor sorting systems decreases the amount of time employees spend in processing products and increases the amount of products that can be processed within a single shift. The use of smart conveyor systems reduces the risk of products being directed to the wrong shipping lane and, consequently, sent to the wrong customer. Conveyor systems can accommodate both low and high volume order sizes. Related IndustriesĬompared to manual or conventional sorting methods, sorting conveyor systems offer numerous advantages to industrial shipping facilities, including:

They deliver key components to other subsequent automated devices to enable further value-added processes. These types of systems are often integrated with delivery and assembly conveyors.

Conveyance systems install#

Regardless of the complexity of the manufacturing challenge, we can design, build, test, and install an effective and efficient automation solution. This supports the client with the latest technology, flexible features, reduced mundane labor tasks, and improved efficiency. Our team has the knowledge and experience to optimize and implement solutions to fully meet each customer’s unique needs. They are suitable for use with a wide range of items, varying in both size and weight.Īs an automation systems integrator, Reko Automation specializes in providing factory automation solutions, including conveyor sorting systems. Industry professionals use them to separate products from in-feed conveyor lines and direct them to shipping, palletizing, packaging, and other processing stations. Conveyor sorting systems-also sometimes referred to as sortation systems-are material handling technologies designed to increase the efficiency and accuracy of manufacturing and shipping operations.

0 kommentar(er)

0 kommentar(er)